4 hours, 24 May 2014

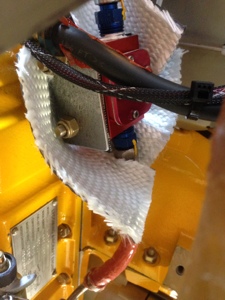

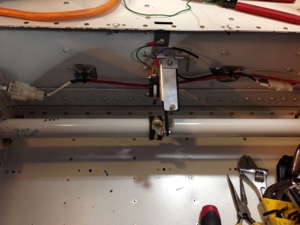

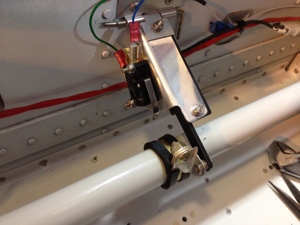

I installed the Anti-Splat Air/Oil Separator and exhaust valve. I changed the mounting structure that held the right side exhaust muffler and pipe to accommodate the Oil Separator drain tube and valve. I also changed the routing of the oil and air drain tube routing and added a section of the aluminum pipe to the blue hose as to route the house out away from the firewall and then back again to the valve that connects to the exhaust pipe.

RV10 Building Adventure

RV10 Building Adventure