July 27, 2013 10 hours.

After an extremely long building pause…… as we were working madly to get the new house into “our” standards we didn’t touch the RV10 once. That was about 3 months of no work on the RV10, not good but we did get 9 new windows installed, more insulation blown in the attic, painted many of the rooms, had carpet installed in three rooms, had a door installed in the master bed room, installed three ceiling fans, fixed multiple wiring issues, installed some flooring and had the roof resealed and glazed. and we still aren’t finished.

After moving the RV10 out of the corner of the hangar from behind the many piles of moving boxes we started with setting up shop. We originally planned on cleaning the hangar and repainting before the hangar move in but the timing just didn’t work out. We decided to just concentrate on the RV10 build and worry about the hangar later. We rather be flying first before we have a great looking hangar.

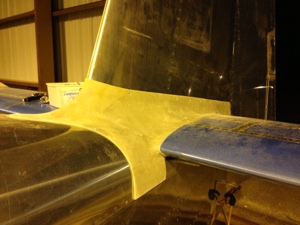

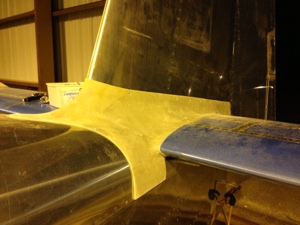

I started working on the empennage section and installed the horizontal and vertical stabilizers and the horizontal elevators. After removing and installing these several times I finally had the empennage fairing installed/trimmed properly to my content. I then installed the rudder, although I did not torque the bolts for this since likely it will come back off once again. All the bolts that attach the vertical and horizontal parts are torqued along with the horizontal elevators.

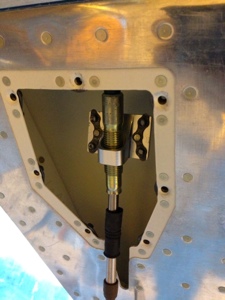

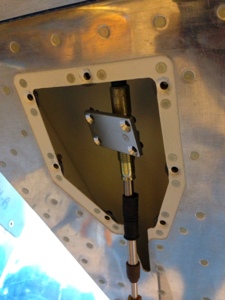

I did realize that my trim tab machined nuts are machined at the wrong angle. Very disappointing since i machined them back when I “had” access to the machine shop. Now that I changed jobs I will have to buy them from IFlyRV10.com.

RV10 Building Adventure

RV10 Building Adventure