8 hours, 29 May 2014

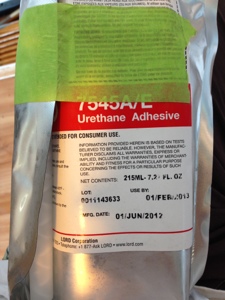

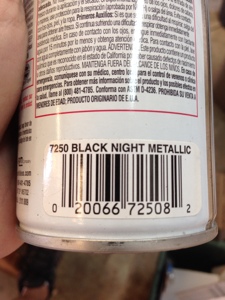

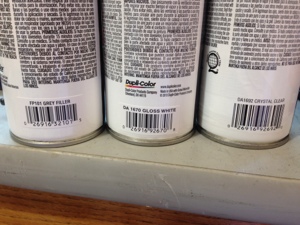

I received the Cee Bailey’s windows on Thursday 29th, 2014. What a great product. Very minimal sanding required to fit all the window recesses. I used the LORD adhesive sold by Aerosport’s – Geoff. I already had the applicator gun. Other than the prep work for fitting and sanding the windows then tapping the all the process went very easy. I am very disappointed in my lack of skills when it comes to working with the adhesive and sticking the windows in. Overall the windows look good and are installed. The interior sides of the windows are finished. The outside of the windows will take some time to complete.

The front wind screen fairing is another story. Again I am a little disappointed with my skill set on this also. Needless to stay there is lots of sanding involved. I really screwed up on where I placed the upper fiberglass fairing tape line. I wanted the line to be as low as possible and it turns out I have it about two inches to high. I am already a short persons and fear this will come back to bit me in the rear when I cant see over the window properly. the main issue is that I already sanded the window.. oh well.

RV10 Building Adventure

RV10 Building Adventure