System page includes Avionics. Electrical Wiring and Lighting

Category Archives: Systems

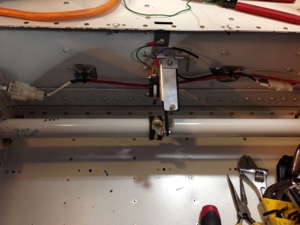

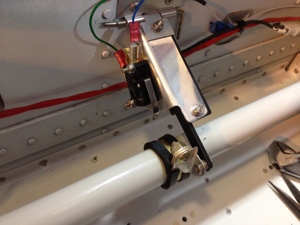

Close out panels and AOA switch

April 30, 2014 3 hours

I decided it would be best to start closing up the panels in the back of the airplane along with securing the wires being routed in these areas. I also installed the AOA switch to the flap sensor so when the flaps transition out of the -3 degree setting the AOA is alerted to the configuration change.

I also installed the transition from the evaporator tot he AeroSport overhead. I drilled a couple of holes and added some rubber door seals. I also installed the close out over head panels to the overhead. It looks good but sadly I scratched the overhead when I was working with the AeroSport Headliner inserts.

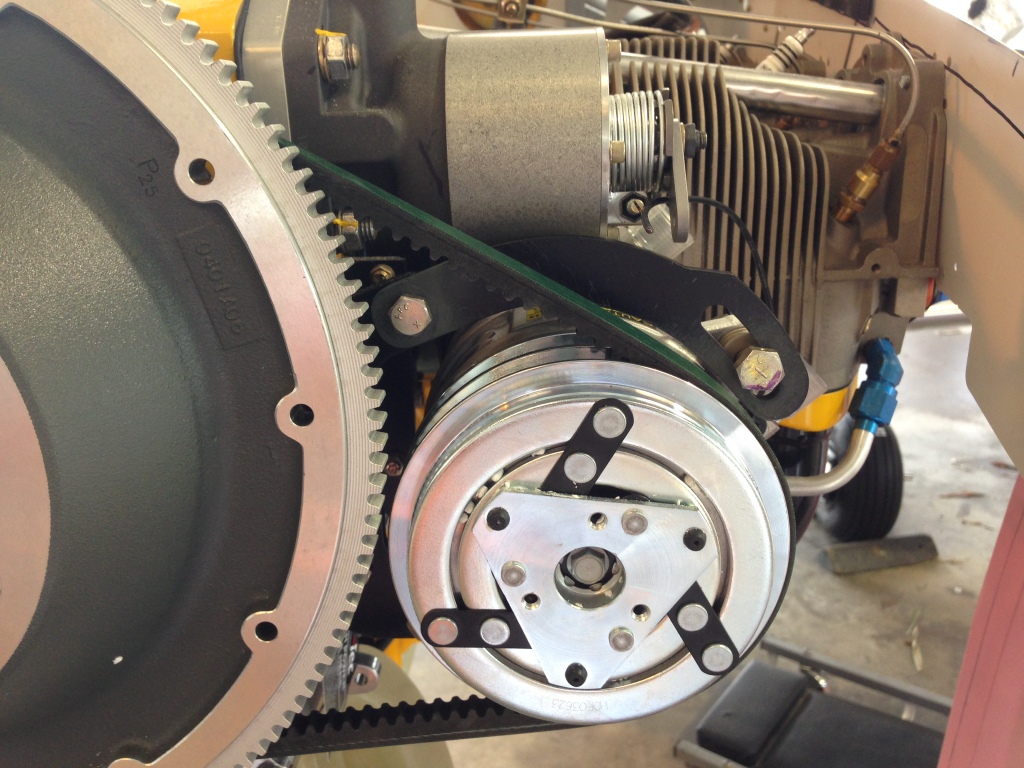

AC Compressor

Wednesday 26th, 2014. 2 hours

I received a replacement AC Compressor from John Strain at Flightline AC. It seems the first compressor I had received had a much larger diameter clutch pulley on it not allowing it to be mounted to the engine while using the standard “green” belt. John sent me the new compressor and I went to work fitting it to the engine. The pictures only show the ring gear as “in place” since I am working on the cowling baffling and didn’t want the prop in the way.

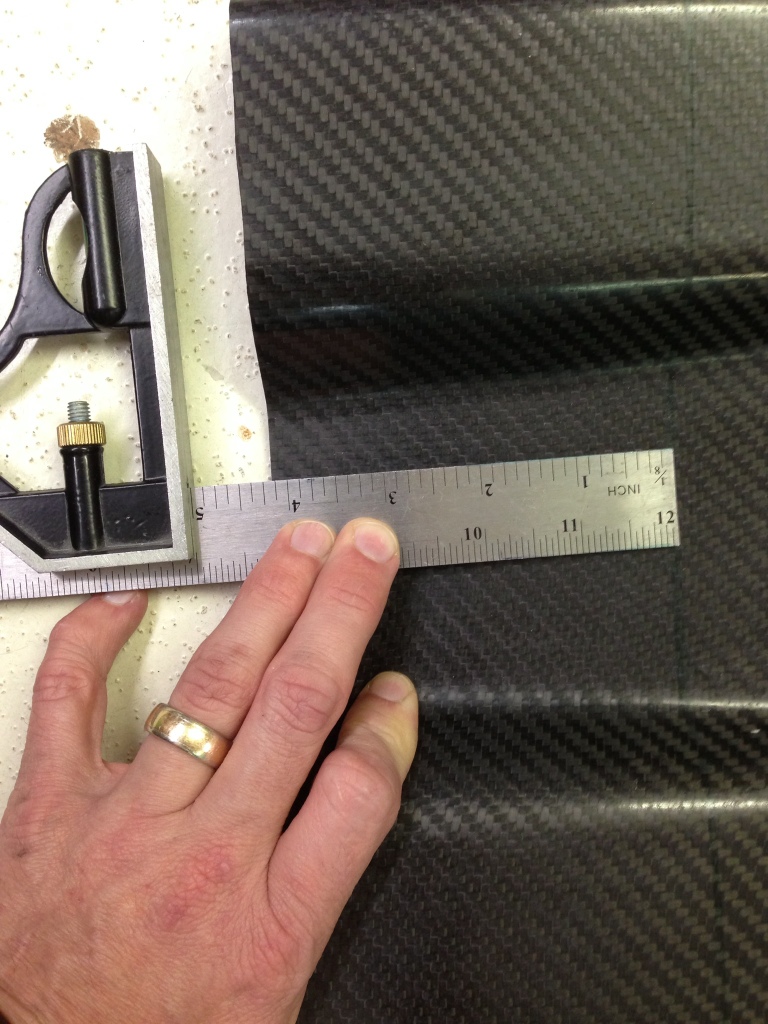

I had to modify the tension adjustment arm for the compressor mounting bracket since it was about 1.5 inches to long. I shortened it and re drilled the mount hole.

I had to modify the compressor mounting holes on the compressor itself. These are threaded as a standard configuration so I made the holes clearance holes so I could use through bolts.

Overhead cabin transitions from Evaporator

March 16th, 4 hours. I received back the molded transition piece from John at Flightline AC that was produced from the transition piece I made. Overall the piece looks fantastic but we both knew the piece would need trimming to properly fit since they made the transition piece based upon little to no extra information. In one of the pictures you can see how the original intent was to be, however based upon this installation and many other likely to follow for others the transition piece will need to be modified a bit more to be mounted much higher. I trimmed off the top portion of the piece that wraps around the evaporator. I then lowered the inside backing wall that helps seal the evaporator face to the transition since I had to raise the entire tranission up higher. The tranistion now mounts up to the overhed, evaporator and cabin top very nicely. I still need to locate a mounting plate for the front mounting hole already in the evaporator and place a rubber or foam gasket material on the surface that require to be sealed. I think John will revise his mold slightly to accomidate the angle differences but overall the tranisiton piece is very near it final shape.

John placed to vents in the transition piece to help throttle the air flow plus allow the cold air to be more quickly recirculated thru the evaporator to help cool down the cabin quicker and achive an overall lower temperature.

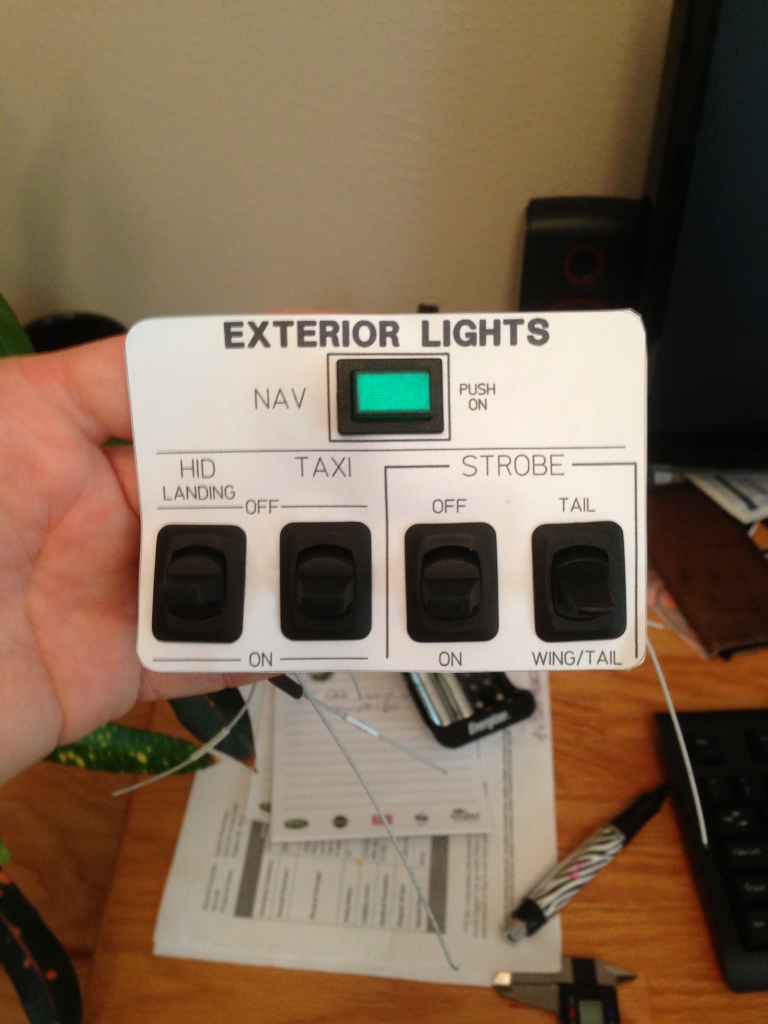

Overhead Switch, Air Vents, and Light install

March 9th, 2013 (9 hours for all). Received the overhead switch panel from Panel Express and install the switches to see how it would look. I had to cut out a portion of the overhead to accommodate the switches to be removed with the panel. I had originally thought that I would mount the switches into the thru holes capturing the overhead panel and the switch panel. I quickly realized that would be way to hard to accomplish with little to no hand room. (Total time for this work and prior, 4 hours)

I then moved to installing the overhead air vents that John sent me from Flightline AC. He searched long and hard trying to find the appropriate vents that can accommodate the large amounts of air the evaporator can flow. The air vents are very nice and are low profile so not to protrude into head space. The only issue is they might be a little more difficult to adjust since they are low profile but I think they will work perfectly over all. I did need to trim the retainer ring down a couple of inches since it was to tall to fit between the cabin top and the overhead. I used a very small amount of grease on the retaining plastic nut that holes the body of the air vent so to create more drag on the nut and hopefully keep it from loosing on it own. Since these vents are larger than the standard air vents the overhead was designed for I had to take the hole diameter out to the very edges of the mounting face. Using the air grinder with a round sanding drum helped in the process of fitting the vents. (3 hours)

Moving on to the led lights, we installed four of the Aveo Eyebeam Touch lights into the overhead. I had already drilled out the holes to accommodate them in a prior step so I installed them and connected the internal wiring of the overhead to the lights. (2 hours)

At some point later in the build process when the interior starts to become complete I will install strip LED lighting to the outside edge of the overhead. This will provide the cabin with lighting and will be dimmable.

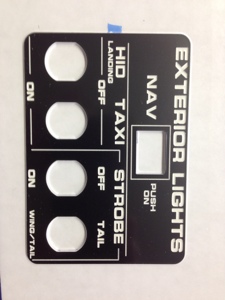

Overhead Switch Panel design

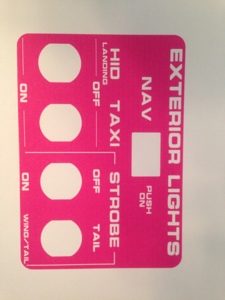

March 3rd, 2013 I continued working on the overhead panel. I will be mounting the Landing, Taxi, Strobe, Nav, and strobe wing/tail select switches in the overhead. I installed the front seats and overhead to verify the switches are accessible. While the switch labeling wont necessary be in front of you for easy viewing it will be easy to read and will be come muscle memory once you remember where the switches are and the order they are in.

I am using Front Panel Express to create and build the panel in. It will be black with white lettering. For some reason my printer decided to printout the scale panel in a shade of pink. Sure my wife would like that. I cut out the holes in the panel t verify switch placement and spacing. once everything was satisfactory to my likening I order the panel. Worked about 8 hours.

Overhead light and wire work

March 2nd 2013 I spent the day working with the overhead attaching a couple of wire run conduits and wire tie down points. I epoxied all of those in place and then started to run the wires that would be installed in the overhead. Four Aveoflash led lights will be installed, two aft overhead the passengers and the other two will be over the front seats. I cut the mounting hole for the two rear lights but did not cut the front two holes since they will be mounted in the front aluminum panel that attaches to the overhead. I am waiting on a circle cutter from Aircraft Spruce.

I terminated the four wires that will be connected to the Aveaoflash led lights and ran two extra wires with connectors for the overhead led stripes that will mounted along the outside of the overhead once the interior gets installed. worked about 6 hours.

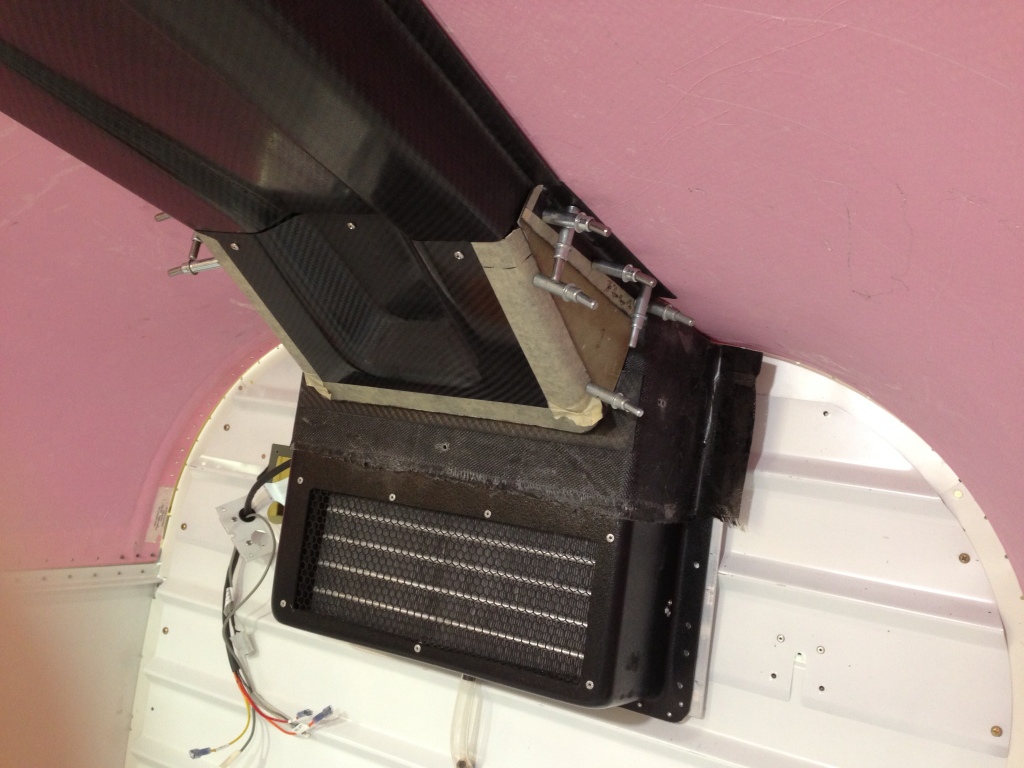

Flightline Evaporator to Overhead transition

Feb 23rd, 2013, 8 hours. Started the morning by using West Epoxy Systems to adhere almost all the overhead tranistions toagther. I did not adhere the ramp section to the close out panel that attaches to the evaporator yet. I still need to attach the ramp union piece to the overhead section that will remain with the overhead mounted to the cabin top. This will require everything to be in place and then some epoxy will be used to temporarily hold the angle required. Then I can final epoxy it in place to the overhead.

Flightline AC Evaporator and overhead tranistion

Friday 22nd, 2013 (2 hours.) I took the backer/closeout piece of fiberglass that connects to the face of the evaporator and cut the two air exhaust holes. Added the three holes for mounting the piece directly to the evaporator.

I then proceeded to drill and cleco all the pieces together while they were in place.

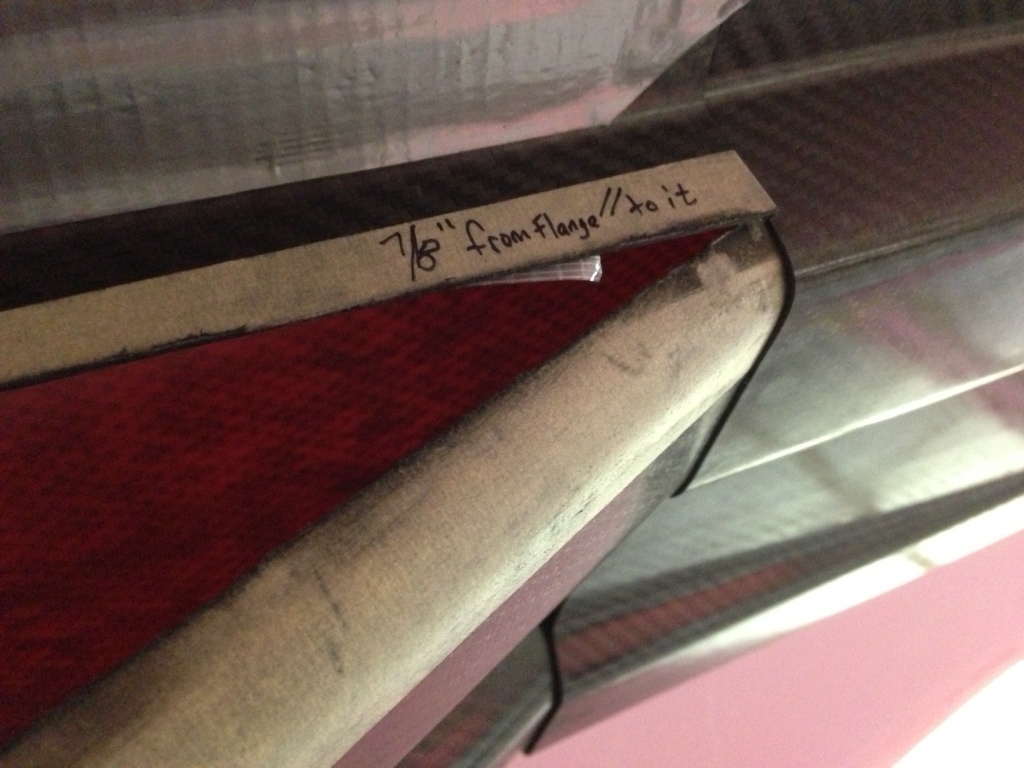

Flightline AC Evaporator to Overhead Transition work

Feb 21, 2012, worked 2 hours. Apparently the brain storming paid off at least for now. I made a couple more cuts on the largest of pieces cut off from the overhead. I trimmed the three flanges from the main overhead section that would normaly butt up to the baggage bulkhead. The side flanges are cut off to 7/8″ measured parallel to the flange. Both sides of the overhead were cut off. I then cut off the rear flange section measured 3/4″ parallel to the flange. This left three pieces that I can attach individualy to the overhead that will be used as the skeleton for the over all transition piece. Pictures are attached to help explain the process.

Flightline AC overhead to Evaporator transition

Feb 20, 2012, worked 2 hours. I decided to cut back the over head another 4 inches to make the ramp angle less between the evaporator and overhead. Once the cut was made I spent the majority of the remaining time figuring out my Go Forward plan. Lots of brainstorming going on. My skill set isnt very big when it comes to this type of thing so I am limited on what experience I can pull from.

RV10 Building Adventure

RV10 Building Adventure