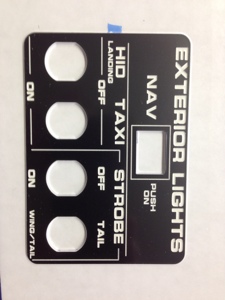

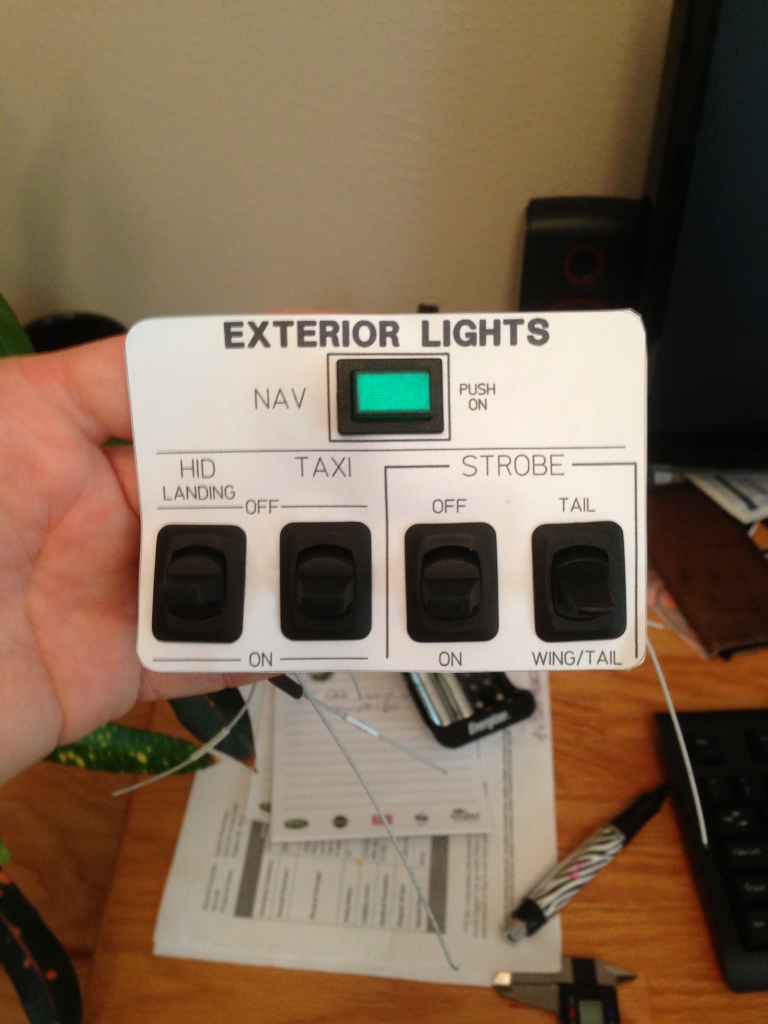

March 9th, 2013 (9 hours for all). Received the overhead switch panel from Panel Express and install the switches to see how it would look. I had to cut out a portion of the overhead to accommodate the switches to be removed with the panel. I had originally thought that I would mount the switches into the thru holes capturing the overhead panel and the switch panel. I quickly realized that would be way to hard to accomplish with little to no hand room. (Total time for this work and prior, 4 hours)

I then moved to installing the overhead air vents that John sent me from Flightline AC. He searched long and hard trying to find the appropriate vents that can accommodate the large amounts of air the evaporator can flow. The air vents are very nice and are low profile so not to protrude into head space. The only issue is they might be a little more difficult to adjust since they are low profile but I think they will work perfectly over all. I did need to trim the retainer ring down a couple of inches since it was to tall to fit between the cabin top and the overhead. I used a very small amount of grease on the retaining plastic nut that holes the body of the air vent so to create more drag on the nut and hopefully keep it from loosing on it own. Since these vents are larger than the standard air vents the overhead was designed for I had to take the hole diameter out to the very edges of the mounting face. Using the air grinder with a round sanding drum helped in the process of fitting the vents. (3 hours)

Moving on to the led lights, we installed four of the Aveo Eyebeam Touch lights into the overhead. I had already drilled out the holes to accommodate them in a prior step so I installed them and connected the internal wiring of the overhead to the lights. (2 hours)

At some point later in the build process when the interior starts to become complete I will install strip LED lighting to the outside edge of the overhead. This will provide the cabin with lighting and will be dimmable.

RV10 Building Adventure

RV10 Building Adventure