April 30, 2014 3 hours

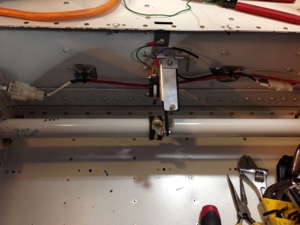

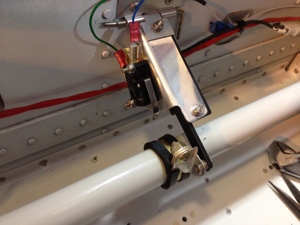

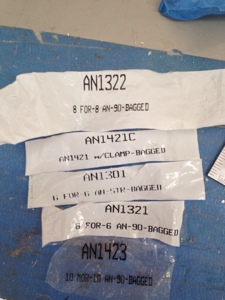

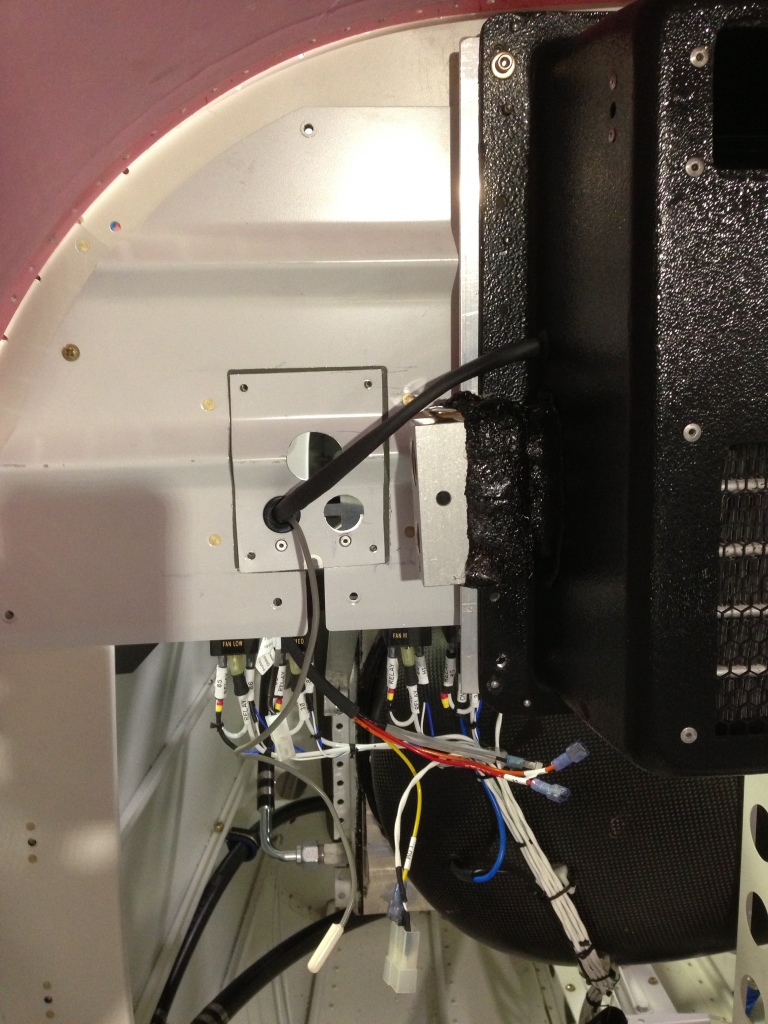

I decided it would be best to start closing up the panels in the back of the airplane along with securing the wires being routed in these areas. I also installed the AOA switch to the flap sensor so when the flaps transition out of the -3 degree setting the AOA is alerted to the configuration change.

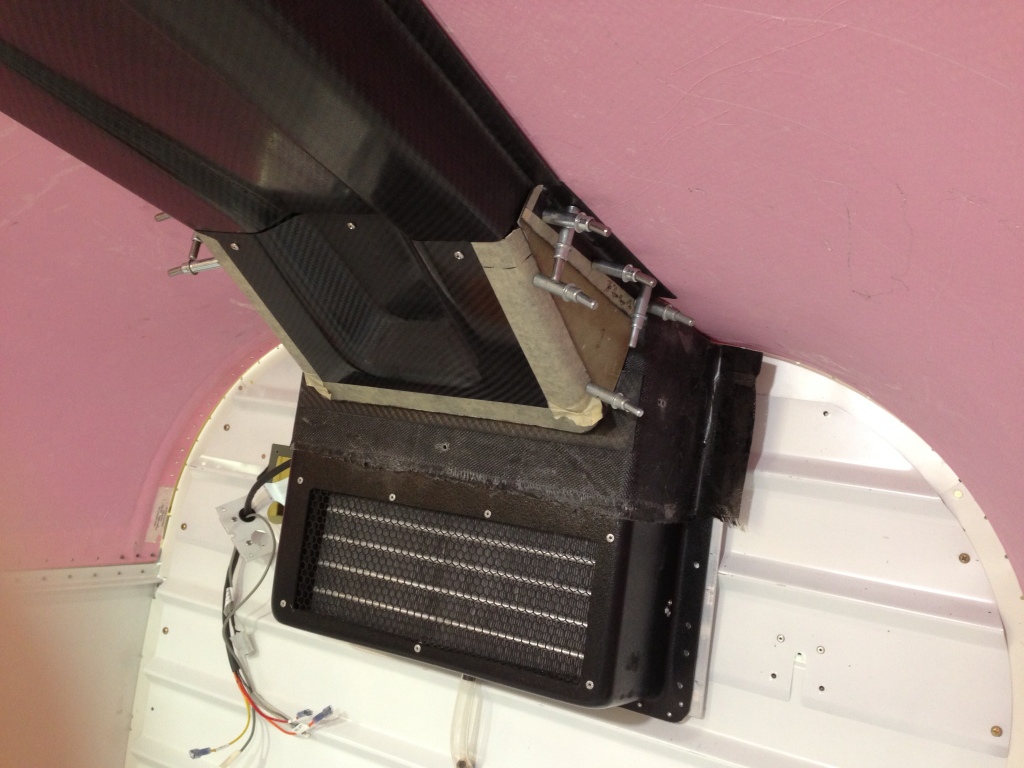

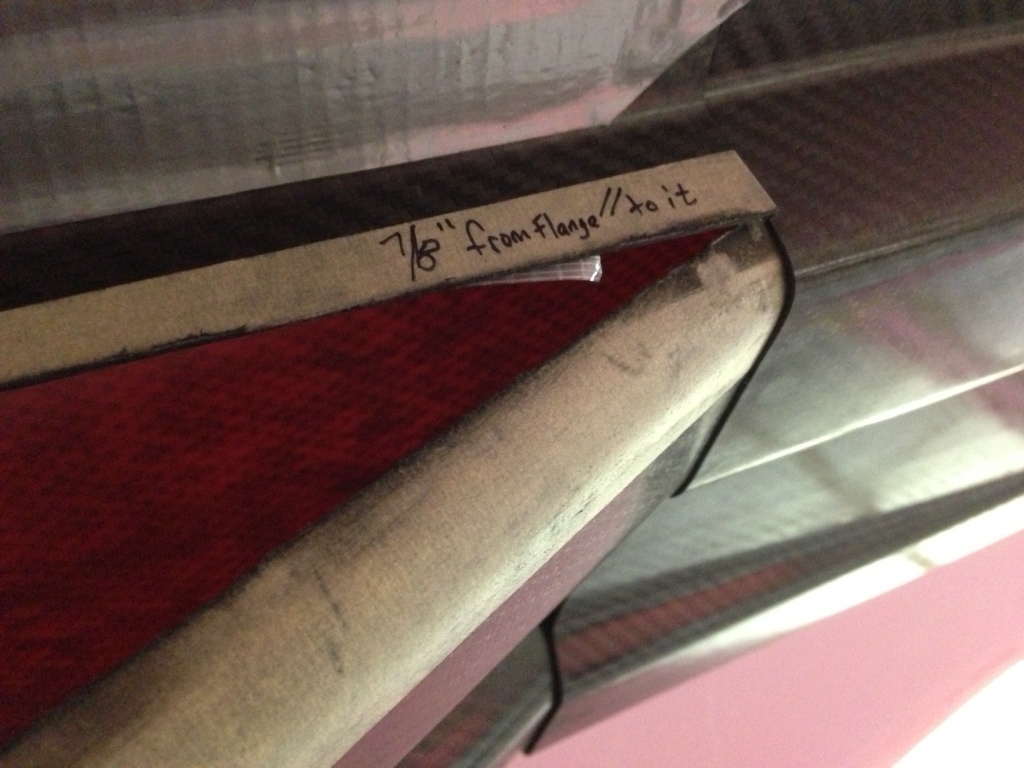

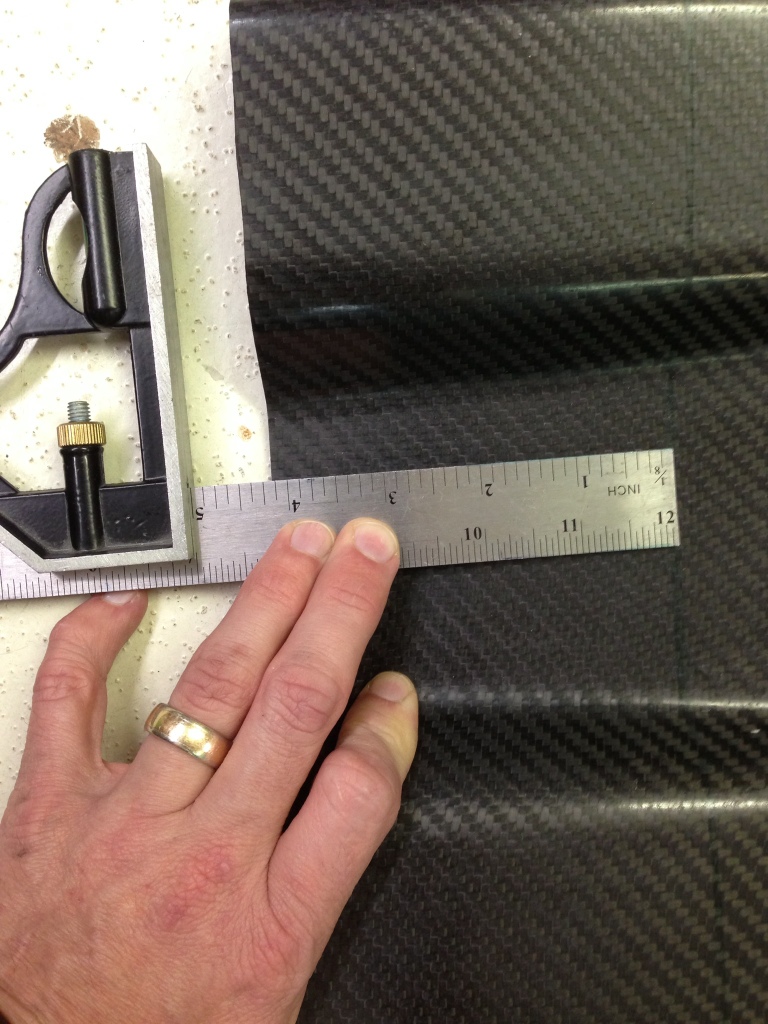

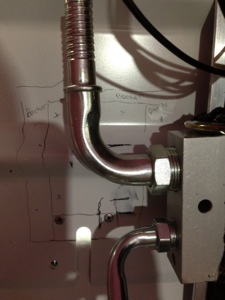

I also installed the transition from the evaporator tot he AeroSport overhead. I drilled a couple of holes and added some rubber door seals. I also installed the close out over head panels to the overhead. It looks good but sadly I scratched the overhead when I was working with the AeroSport Headliner inserts.

RV10 Building Adventure

RV10 Building Adventure