2.5 hours, 25 June 2014

After spending many hours converting the CAD file I had for the original left side panel into Front Panel Express I received the final product in the mail yesterday. I must say overall there were only 2 issues that I saw once installing the panel. The lower right hole for mounting the AOA screen was not all the way through drilled. The IGN/ECU switch panel bezel was larger than I thought I had measured and thus is “runs” over or “covers” a small portion of the horizontal line denoting ECU 1 and ECU 2 form the IGN switches plus the word “LIGHTING” is slightly covered on the bottom side of the bezel. Overall I see no issues with this.

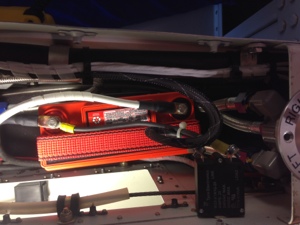

I pulled out all the items out of the panel and swapped over the back plates holding in the G3X screens to the new panel. This required match drilling and counter sinking for the rivet. I installed the new panel with only one issue as I dropped a very small nut that holds one of the rheostats in place for dimmer control. I could not find the nut and suspect it fell all the way down to the sub floor. No good… now I need to find a replacement. Plus I dont have a clue where that one went to and I made it a point during the entire build to ALWAYS find the items that “got away”.

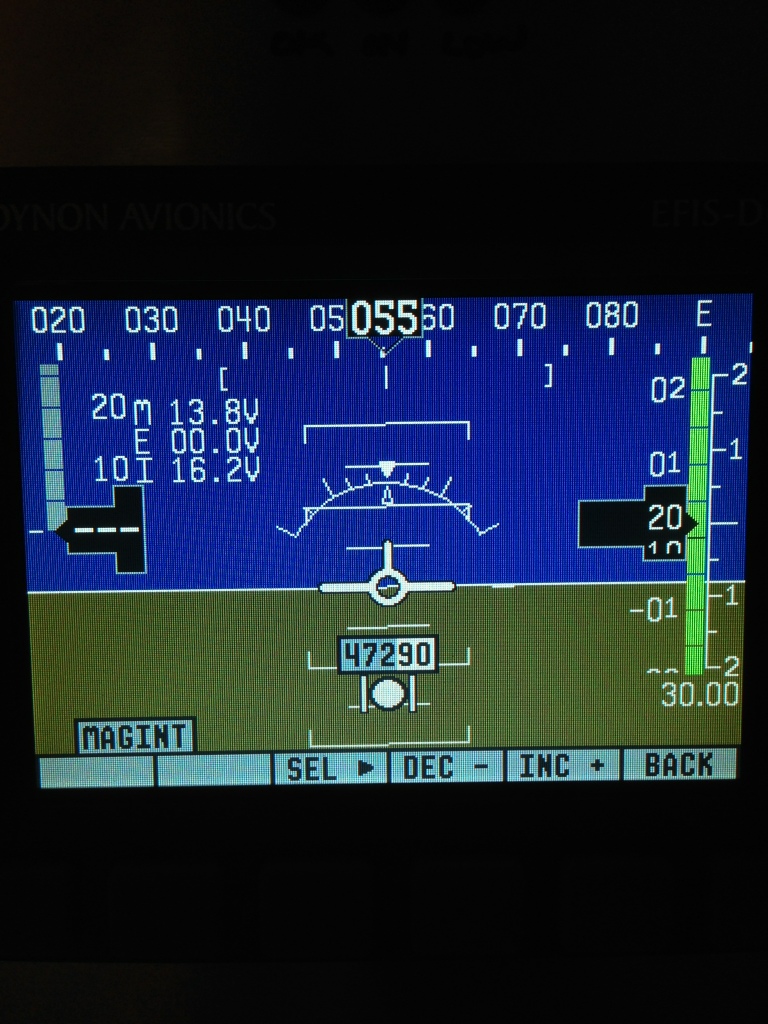

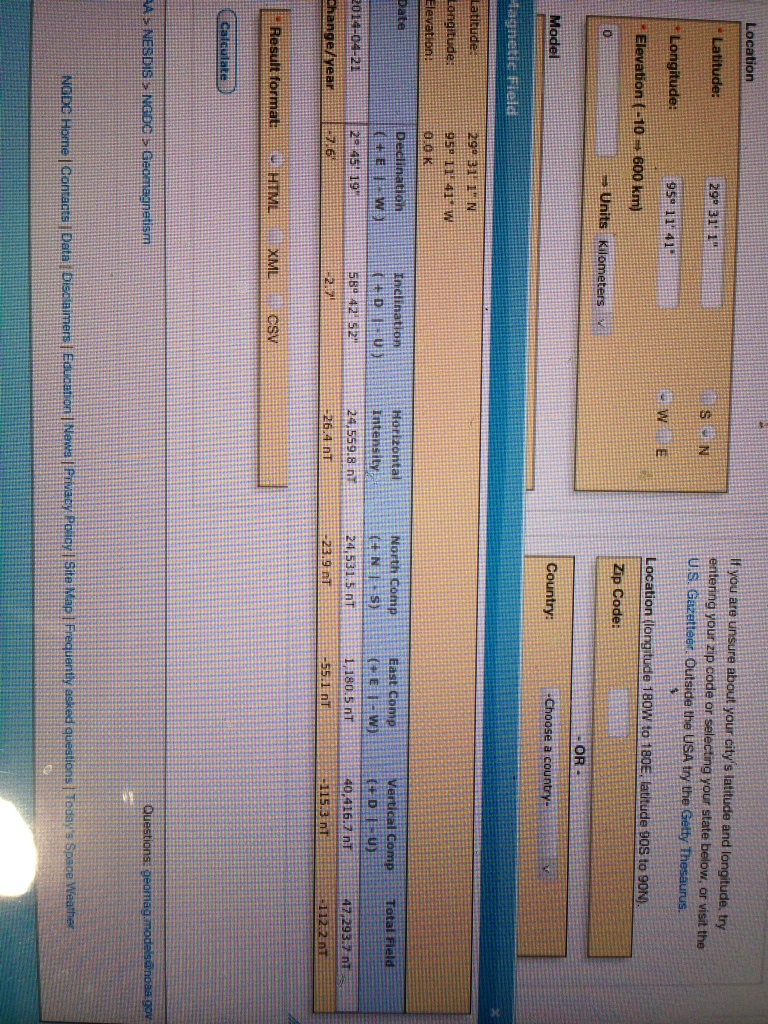

Ops check good!

RV10 Building Adventure

RV10 Building Adventure