Not sure on the date of when the Aerosport panels arrived since I got rather busy with work and other things going on. My best guess is they arrived in early November.

Date Nov 7th, 2013, 16 hours

I spent much of my time beginning to understand what the task at hand was. I laid most of the components out in the panel. There were several holes and tolerances that were either wrong size (too small). Some of the holes being smaller actual was ok since I hadn’t determined the final LED signal light I wanted to use yet until I saw it on the panel. One of the dimmer control knobs is rather close to the Left PFD but this is likely a non issue.

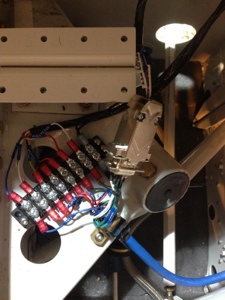

I continued with understanding how to mount the avionics trays. This took a bit of effort to get them correctly aligned where I wanted them. I used various support behind the panel to anchor the trays to each other and to the sub panels. I believe I have captured enough attach point to secure the trays and the weight they will be holding.

Date Nov 9th, 2013, 8 hours

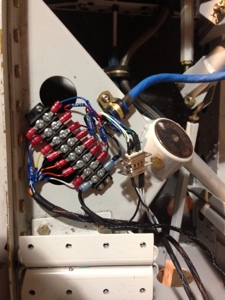

I then started on wiring. I introduced the harness to the sub panel for the first time and got a good look at the real “task at hand”. I put the VPX Pro back into place to understand how the harness routing would be effected. I did change the way I was going to originally route the harness since it quickly appeared that I could not route all the cable thru an opening I had originally thought would work. It would have worked if I had attached the harness to the back of the trays before installing them but either way the over goal was still captured. Many hours spent on basic harness routing and planning.

Date Nov 10th, 2013, 8 hours

Harness termination begins. I started with connecting the VPX Pro to various connections coming from the harness. I decided to not connect the CO monitor to the GEA24 Discrete In 2 J244-42. I choose to not connect this since I have a dedicated yellow LED in the panel. I disconnected the Trim, Aileron and Flap Position sensor wiring form the GEA24 unit. The VPX Pro is sending the Trim, Aileron and Flap Position sensor status to the MFD via RS232. I removed the Main Bus Volts wiring J244-25 and Main Amps J244-36/37 to allow the VPX Pro to provide this information to the MFD.

Date Nov 16th, 2013, 8 hours

Wired the AFS AOA, CO unit and defrost fans.

RV10 Building Adventure

RV10 Building Adventure