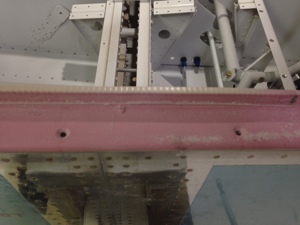

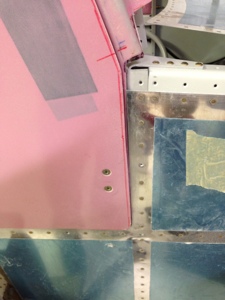

December 27-28th, I continued to work on fitting the McMaster door seal to the door openings. I cut a piece of the seal and put epoxy mixture inside of it and pushed it into place. I allowed this to cure and then continued with the remaining portion of the doors after pulling the seal off and cleaning up the rough excess epoxy. This method allowed a nice holding edge to be formed for the seal so hopefully it won’t slip off later.

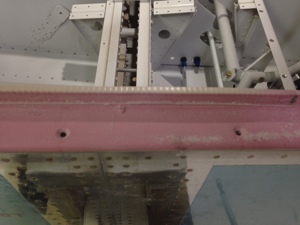

I also worked on the tunnel and added the access panel to the left side. I have decided to put one of the PC680 batteries in the tunnel since the air conditioning unit is behind the luggage bulk head. It has been discussed before about the CG issues of the RV10. With weight of the AC unit and the oxygen equipment in the back. It is highly likely I will encounter a CG issue before I reach gross weight so the batteries need to be moved forward. If it is determined that a battery needs to be moved aft, the original battery location is reserved for exactly this type of scenario. Either way we should be able to cover the CG issue once the aircraft is totally built out. There will be a PC680 mounted on the firewall also.

Consideration needs to be given to the fact that the correct choice of prop needs to be made to help control the total weight and CG requirements. Either the Hartzel or MT 3 bladed prop will be my choice.

Spent 7 hours working mostly all the above mentioned work.

RV10 Building Adventure

RV10 Building Adventure